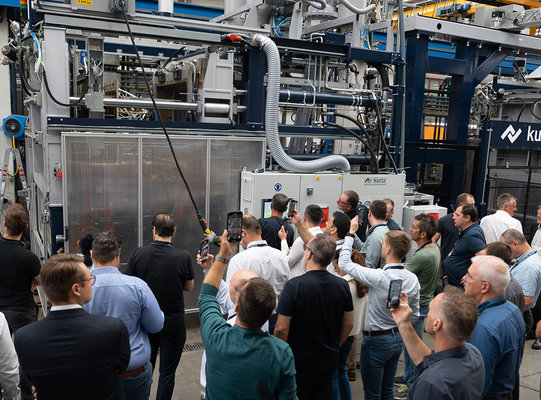

10 years of formnext – and Kurtz Ersa right at the heart of it. At the world´s leading trade fair for Additive Manufacturing (AM), we presented the Flying Ray S, the first building block in our vision for scalable AM technology. The result: an overwhelming response and numerous intensive discussions with potential partners.

formnext remains the international platform for AM innovations. The anniversary edition focused on current challenges: increasing cost pressure, shorter innovation cycles, growing sustainability requirements. With the Flying Ray S, we are providing a concrete answer to these challenges.

Flying Ray S: Maschinenbau meets Innovation

“Maschinenbau is our Business” - under this motto, we showed how visionary technology at Kurtz Ersa is based on sound engineering expertise. The centerpiece of our trade fair presentation was the Flying Ray S, our first system in this technology class. The Flying Ray S sets new standards with its swivel arm technology, which replaces conventional galvo scanners. Our mechanical engineering expertise forms the solid foundation for this technological development.

The innovation offers two key advantages:

→ Consistent quality across the entire build space

The swivel arms position themselves at the perfect angle over each point - the result: consistent component quality, regardless of position and orientation. Components from the first production batch correspond exactly to those from subsequent batches, across all systems. This reproducibility significantly reduces application development time and costs compared to scanner systems. Component qualification and verification times are therefore considerably shortened - a decisive advantage for industrial series production.

→ Scalability opens up new fields of application

The swivel arm technology enables flexible build volume sizes without the need for costly redesign of the machine concept. This shortens system development times and increases our responsiveness to market requirements. In addition, scalability paves the way to production of large-volume components, thereby sustainably expanding the economic scope of AM technology. Applications that were previously outside the size range are now accessible.

AM creates synergies

Two other exhibits impressively demonstrated the breadth of our mechanical engineering expertise at Kurtz Ersa: An optimized foaming tool for particle foam production shows how Additive Manufacturing improves conventional processes. In addition, a customized suction gripper from our 3D printer enables the simultaneous handling of multiple electronic components in Ersa rework systems for the first time. This cross-business-unit collaboration was particularly well received by trade fair visitors and underscored our holistic approach at the Kurtz Ersa Group.

Bringing innovation to life

A special highlight at the trade fair booth was the augmented reality (AR) presentation of the Flying Ray S. Visitors were able to immerse themselves virtually in the swivel arm technology and experience how it works from different perspectives. “The AR visualization helped visitors intuitively grasp the complexity of our technology,” summarizes Dr. Astrid Rota, Managing Director, Additive Manufacturing. “We were able to generate enthusiasm quickly and convey the key advantages – exactly what we need for successful partnerships.”

Market launch in 2026 – shape the future with us

The Flying Ray S is the first building block in our AM product portfolio and forms the basis for scalable, customized solutions. With the market launch in 2026, we are actively shaping the future of large-volume Additive Manufacturing - and invite you to join us on this journey. Benefit from our mechanical engineering expertise and contribute your application expertise. Let´s define the next development steps together. We look forward to exchanging ideas with interested development partners!