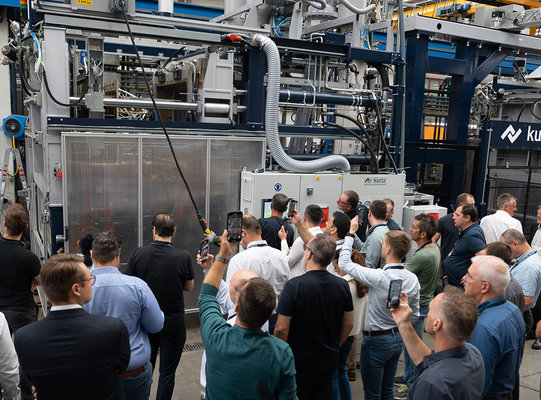

Special products call for a special machine. The ROTO FOAMER is a solution in the Kurtz Shape Moulding Machine series for applications that are becoming increasingly common in the market. Whether in the sports and leisure industry or in the automotive industry.

There are more and more applications in particle foam that require a special machine. This mainly concerns hybrid products consisting of two materials, one of which must be foamed in - and therefore inserted into the foam mold beforehand. These can be products from the sports and leisure industry, e.g., bicycle or ski helmets, which are manufactured using the in-mold process. Many applications are designed for the automotive industry, such as rear seats, headrests, or sun visors, which must be manufactured with a metal insert for stability and fastening purposes.

Production of High-end EPS or EPP Products

To this end, Kurtz Protective Solutions have developed a series of machines that are ideally suited for two components - specifically, the insertion of parts such as films, plastic, or metal parts. The ROTO FOAMER is a shape molding machine for the production of high-end EPS or EPP products with inserts. The first similar concepts emerged in the early 2000s, but they still needed to mature. Today´s Kurtz ROTO FOAMER is a logical further development and is available in several sizes.

The technology of the current system: The insertion of the parts and the removal of the finished products take place parallel to the foaming process. The open and low design gives the operator easy ergonomic access to the tool. Only one operator is required to operate the system and insert and remove the finished products. Optionally, the machine can also be equipped with a robot so that it can operate independently without an operator.

Frame Rotation in less than 5 Seconds

The heart of the machine is the rotating fixed frame. This is equipped with a steam chamber and a mold half on both sides. One side is always dedicated to the foaming process, while the other side faces the operator for removing the finished parts or placing inserts. Since the ROTO FOAMER can rotate the frame in less than five seconds, there is almost no loss of cycle time due to secondary movements. The rotation speed is infinitely variable and can be adjusted to suit products and inserts. The production of standard products without inserts is also possible without any problems. Either the rotating frame is equipped with only one mold half, or both sides are equipped with one mold half each.

Another advantage is the dimensions compared to a shuttle version, in which the steam chamber does not rotate but moves to the left and right of the actual foaming process. This makes the shuttle machine almost three times as wide as the ROTO FOAMER. The shuttle machine requires two operators, as the machine has a removal and insertion position on the left and right. The inserts must also be provided on both sides. This also significantly increases the logistical effort. ROTO FOAMER machines are used in various sizes by several large EPP processors for the automotive industry worldwide and are increasingly in demand.

Highlights ROTO FOAMER:

- Removal and insertion of components takes place parallel to the foaming process

- Small footprint compared to a shuttle version

- Only one operator required; if two ROTO FOAMERs are positioned opposite each other, one operator is sufficient for two machines

- Can be optionally equipped with a robot

- Standard products can be produced without inserts