VIP Customers visit Kurtz Protective Solutions in July

The first Kurtz Technology Days on July 9 and 10 significantly exceeded our expectations and left a positive impression on VIP customers and our Business Unit Protective Solutions. The idea of giving a select group of customers a preview of Kurtz´s highlights for the trade fair in the K year was so well received that further Kurtz Technology Days are planned for the future.

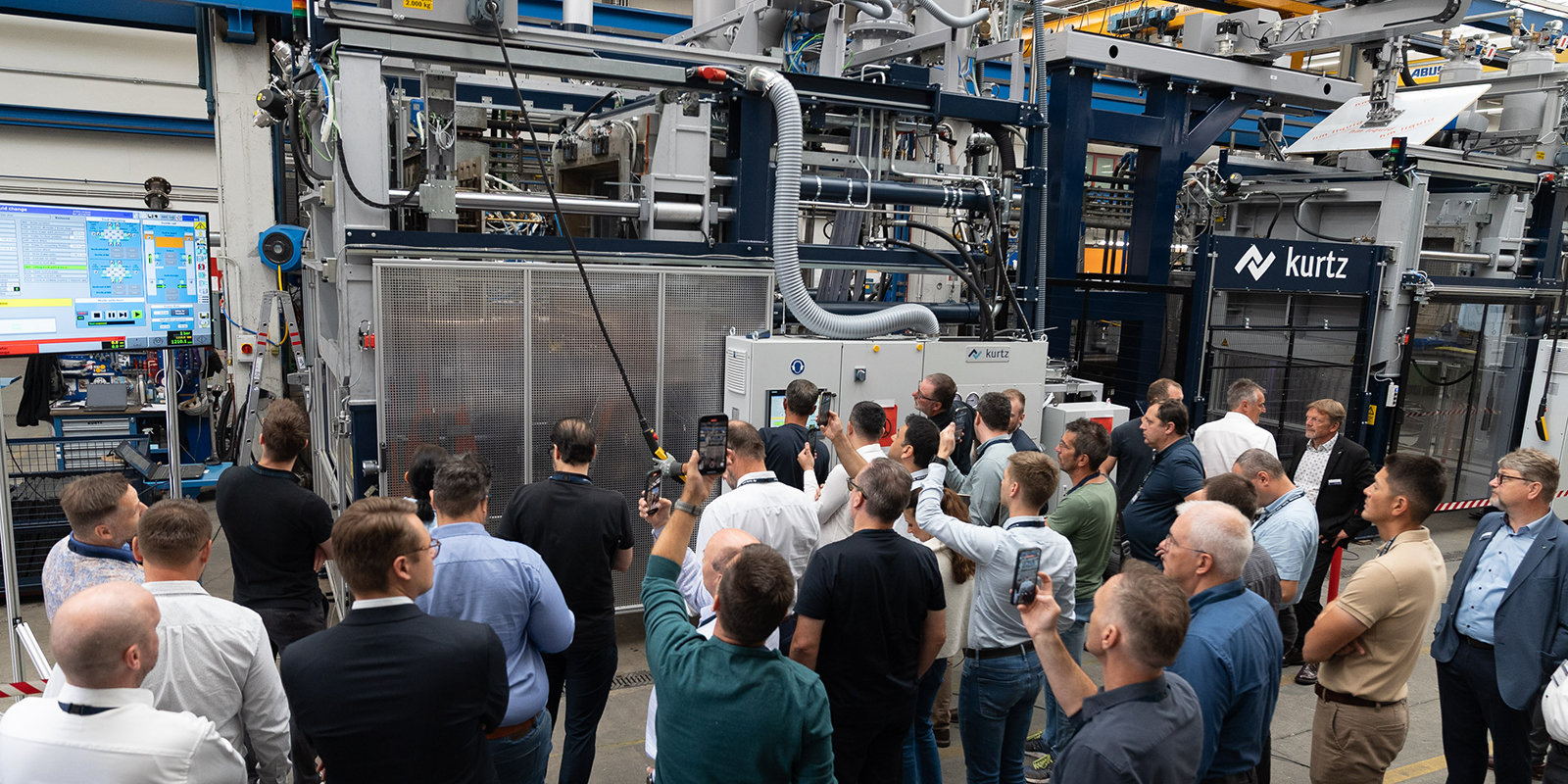

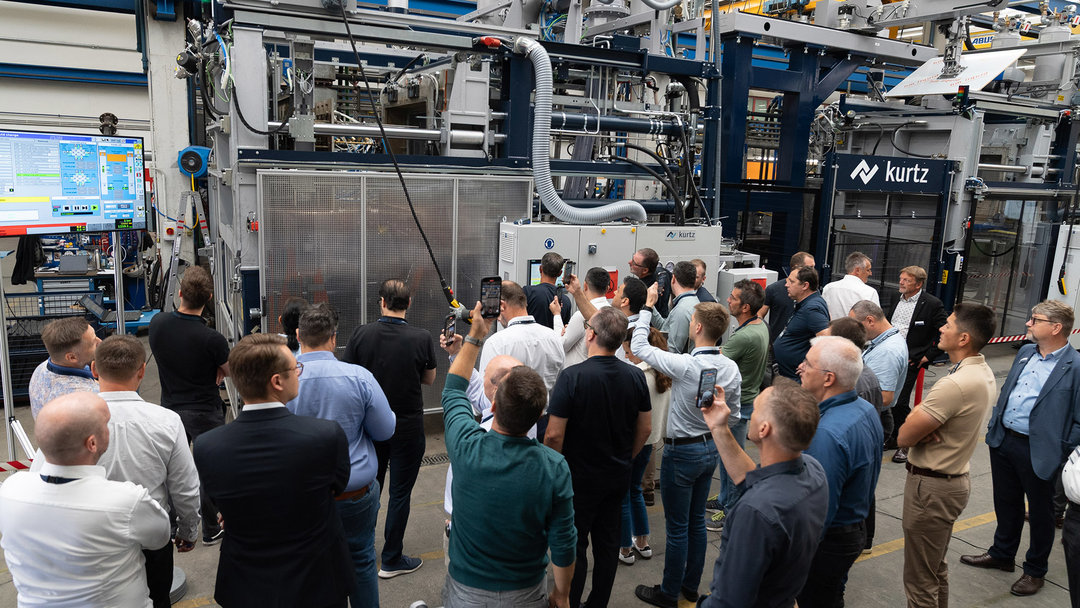

The K Preview fulfilled all expectations. In addition to the presentation and discussion of the new products at the trade fair, the event left plenty of room for discussions and the exchange of information between Kurtz and an international audience. Nearly 40 customers and interested parties made their way to Kreuzwertheim-Wiebelbach to get an exclusive preview of the new Kurtz products. The feedback confirmed to our business unit that its developments are in tune with the industry. At the same time, our colleagues received valuable feedback from the discussions, which helped to further optimize the products in time for the fall and the big stage of the K trade fair.

Kurtz Protective Solutions offered a varied Tech Days program. This included tech presentations on its own developments and a market and trend assessment, as well as an impact analysis for mechanical engineering by division manager Stephan Gesuato. On the first day, two exciting guest lectures and a partner lounge also enriched the program. In the latter, Fraunhofer ICT and Kaneka Belgium B.V. presented raw materials, their special features, and applications. The partner lounge invited lively discussions with numerous sample parts for a wide variety of applications.

The highlight of the Technology Days for VIP customers was undoubtedly the time spent in the assembly hall and the brand-new showroom of Kurtz Protective Solutions, where the new products that had been teased were demonstrated in operation. Among other things, visitors were able to see a new and very fast linear robot for removing molded parts, which attracted great attention with its fast movements. The robot is mounted separately, allowing it to develop its full dynamic potential. It can be used for several machine sizes and can also be retrofitted to existing shape molding machines.

Another gem - and a real eye-catcher with its orange color - was the semi-automated tool change system, which makes tool changes faster, smarter, and safer. It replaces manual, error-prone steps with a guided, automated process - for measurably more stable processes and lower costs per molded part produced.

Semi-automated tool change - for new systems, but also retrofittable

The semi-automated tool change is available with new shape molding machines, as well as for retrofitting on machines in the A-LINE and T-LINE series in sizes M and L. There was also enormous interest in the control of molded part weights - an efficient, sustainable optimization in molded part production. After all, less raw material used means lower costs and less CO2. Last, but not least, Kurtz Ersa Additive Manufacturing rounded off the diverse program by providing an insight into the added value of metal additive manufacturing for the plastics industry and offering a tour of its development department.

We have not regretted our decision to invite only a select group of customers and to deliberately keep the Technology Days small. The select group allowed for an intensive exchange with each individual customer. Absolutely beneficial for both sides. We would like to thank our visitors and partners for the exchange and the two wonderful days at the Kurtz headquarters!