ARIS and the HERMES Project

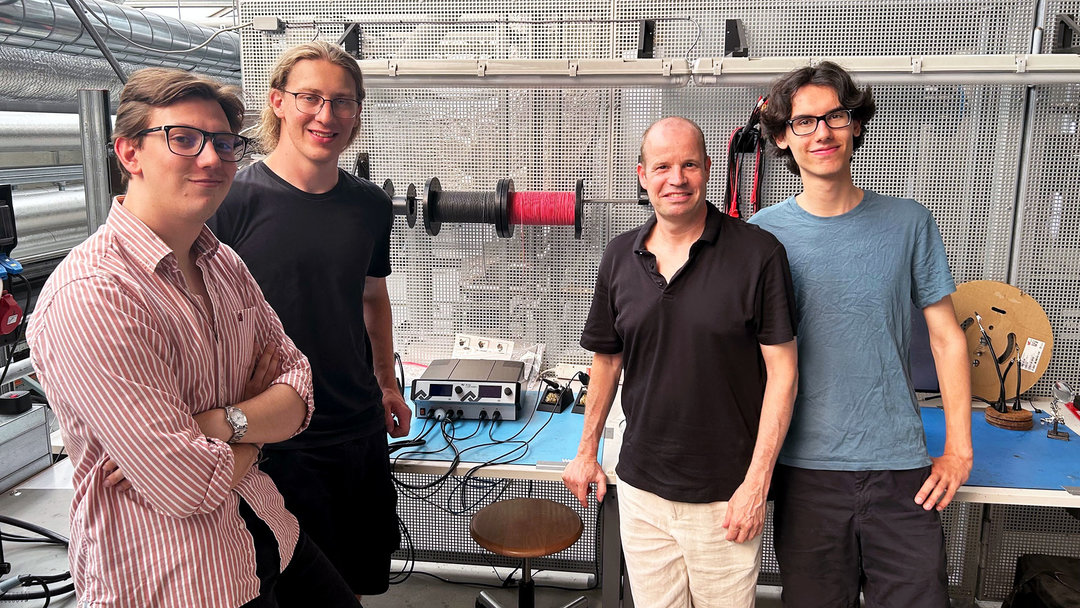

ARIS, the Academic Space Initiative Switzerland, is an organization set up by students from various universities, including ETH Zurich, the University of Zurich, ZHAW, and OST. ARIS´s goal is to train young engineers in the fields of space travel and robotics and to give them their first experience in developing complex systems through practical projects.

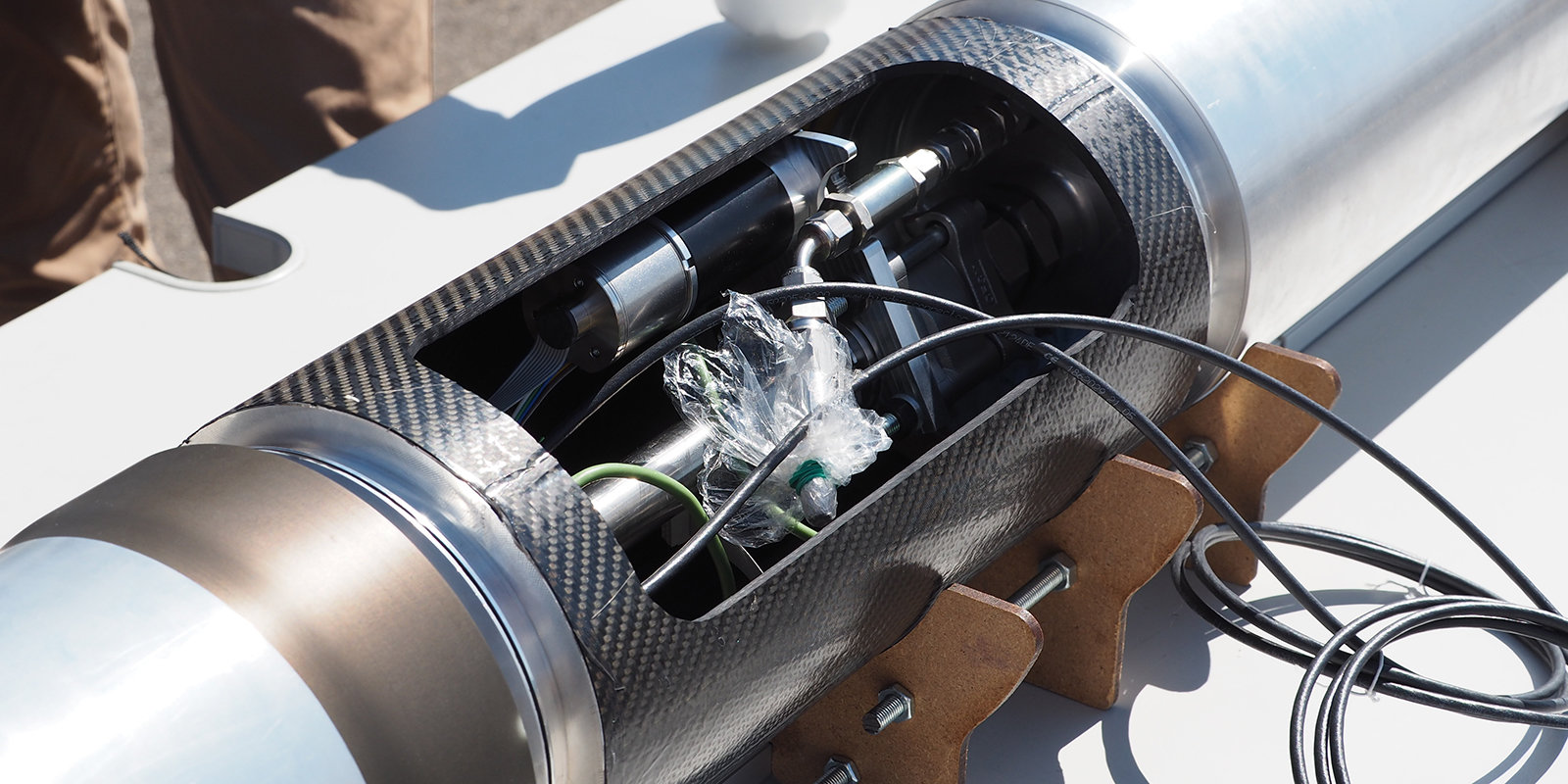

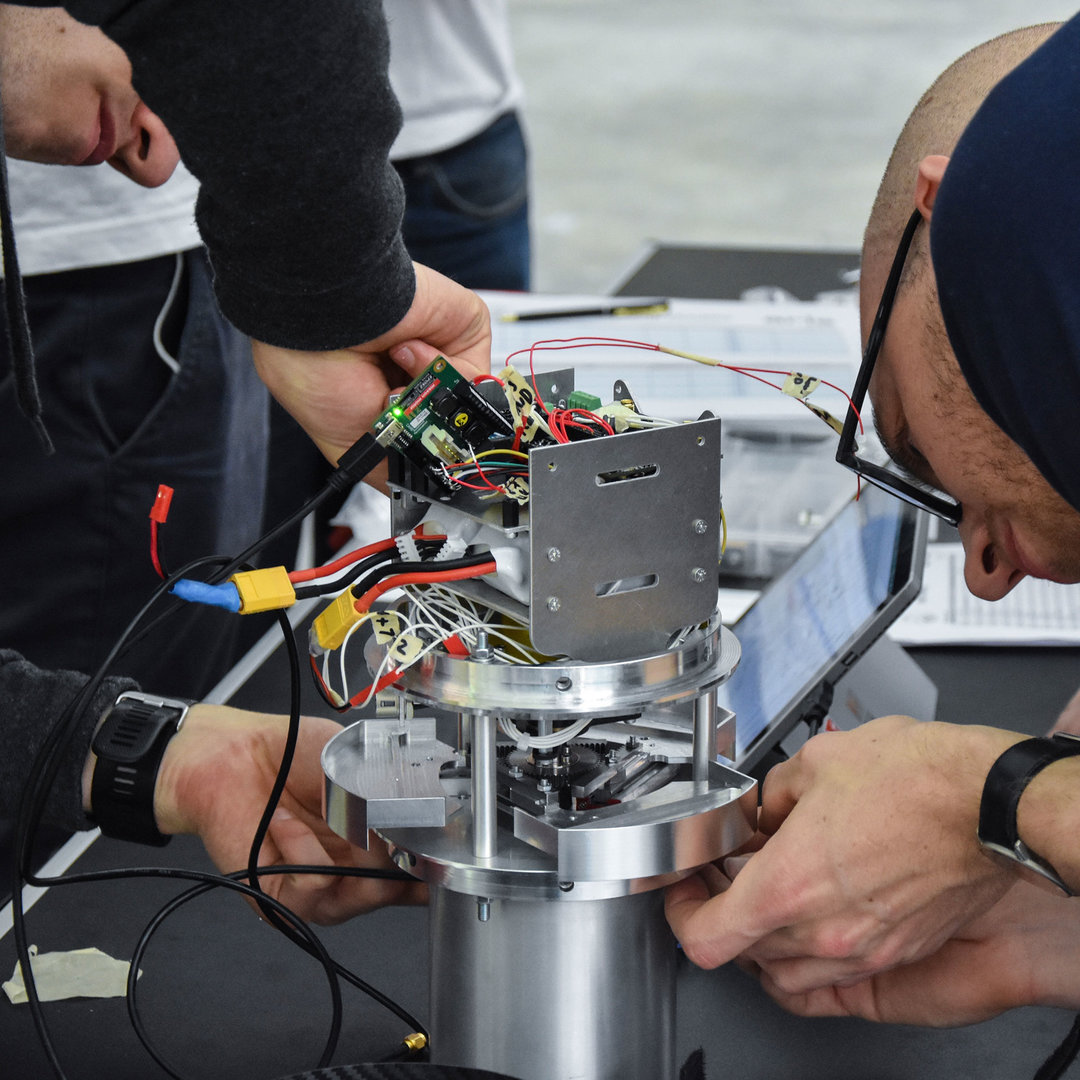

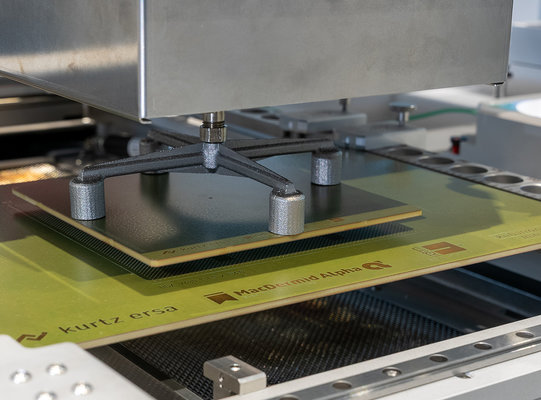

The mission of the Swiss student rocket team with the HERMES project focuses on the development of a two-fluid rocket with a recovery system that will enable the rocket to be reused. The launch took place in October 2025 at the European Rocketry Challenge (EuRoC). A central element of the project was the avionics, which included control, data recording, and communication with the rocket. To this end, the HERMES team developed its own PCBs, which were designed in fall 2024 and then continuously optimized.

Use of the Ersa i-CON VARIO 4

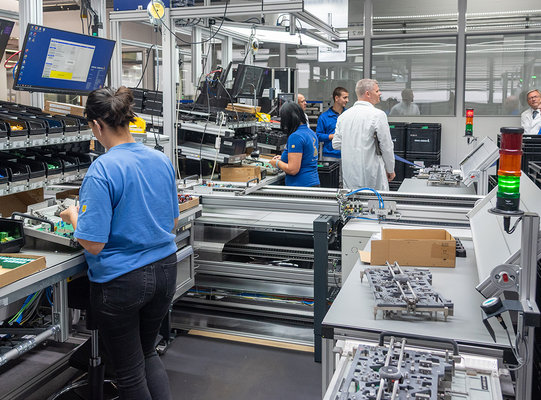

After already having been provided with an Ersa i-CON NANO by Intec AG, we now had the pleasure of using the Ersa i-CON VARIO 4 intensively in the final preparations before our launch at EuRoC 2025. The i-CON VARIO 4 significantly expands the range of tools with its four powerful tools: soldering iron, hot air gun, desoldering iron, and SMD soldering tweezers.

This combination allows all work steps on the circuit boards to be carried out with a single station thanks to the constant readiness of all tools - from soldering and desoldering to the reworking of small SMD components - eliminating the need for constant tool changes. In addition, the soldering tools have an automatic standby mode that lowers the temperature after a certain period of inactivity. This protects the soldering tips and increases the service life of the devices without affecting the working speed.

Significance for the HERMES Project

Thanks to the i-CON VARIO 4, the HERMES team was able to manufacture the avionics boards with quality and efficiency. The versatile tools, precise temperature control, fast operational readiness, and high reliability of the station made a significant contribution to the preparations for the launch at EuRoC 2025.

ARIS would like to express its sincere thanks to Intec AG for its support and for providing the Ersa soldering station, which has made the team´s work significantly easier and contributed to the professionalization of production.

DIE I-CON VARIO 4 TOOLS IN USE AT HERMES

The higher performance of the i-TOOL soldering iron enables efficient soldering of large cables and heat-intensive components. Thanks to its integrated compressor, the i-TOOL AIR S facilitates the desoldering of large components and remains mobile for field tests. The X-TOOL VARIO allows ergonomic, material-friendly removal of THT parts. With the CHIP TOOL VARIO tweezers, small SMD components can be quickly desoldered and soldered in – ideal for frequent adjustments.