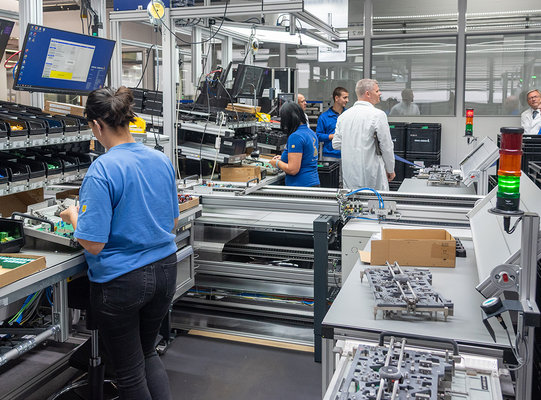

With the VERSAFLOW FIVE, Ersa presents the new benchmark in ultra-high-end selective soldering. Developed for the most demanding applications – from automotive and aerospace to industrial electronics – it combines maximum flexibility, high throughput, and maximum process reliability in a completely new machine design.

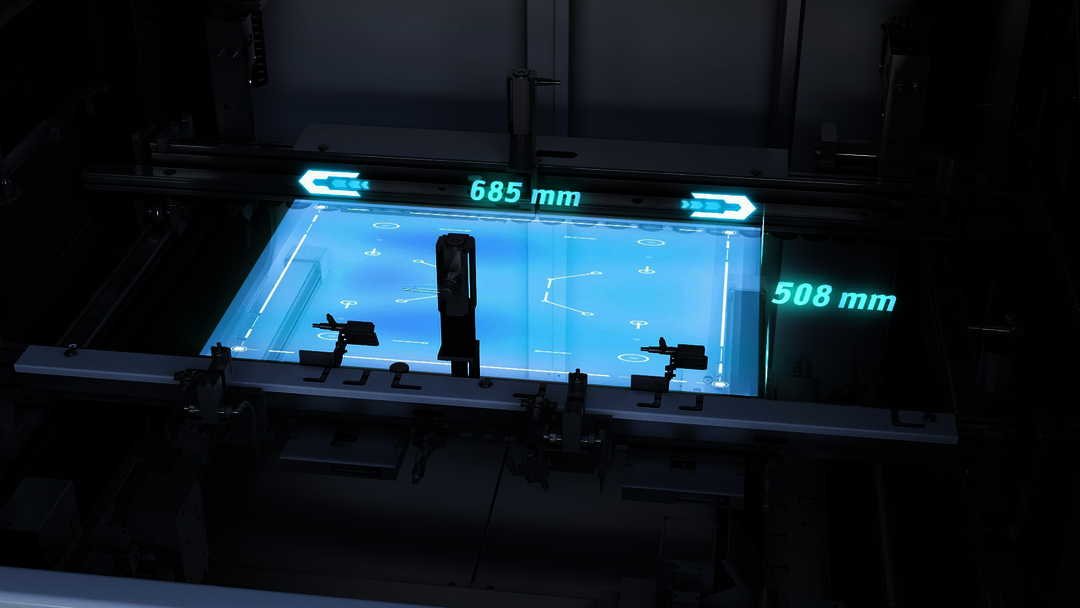

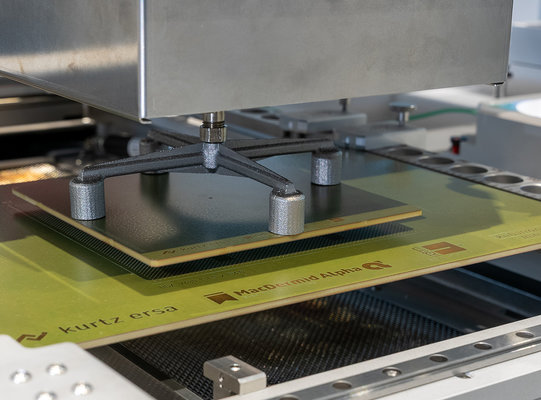

At the heart of the new generation is the VERSAFLEX 2.0 module, which enables both maximum flexibility and maximum throughput. In addition to standard sizes, the FIVE also processes XL assemblies up to 685 x 508 mm. Alternatively, two PCBs measuring 350 x 508 mm each can be soldered in parallel - in synchronous mode for fast panel processing or in asynchronous mode with completely independent programs, nozzle geometries, or solder alloys. Integrated collision monitoring ensures safe operation at all times.

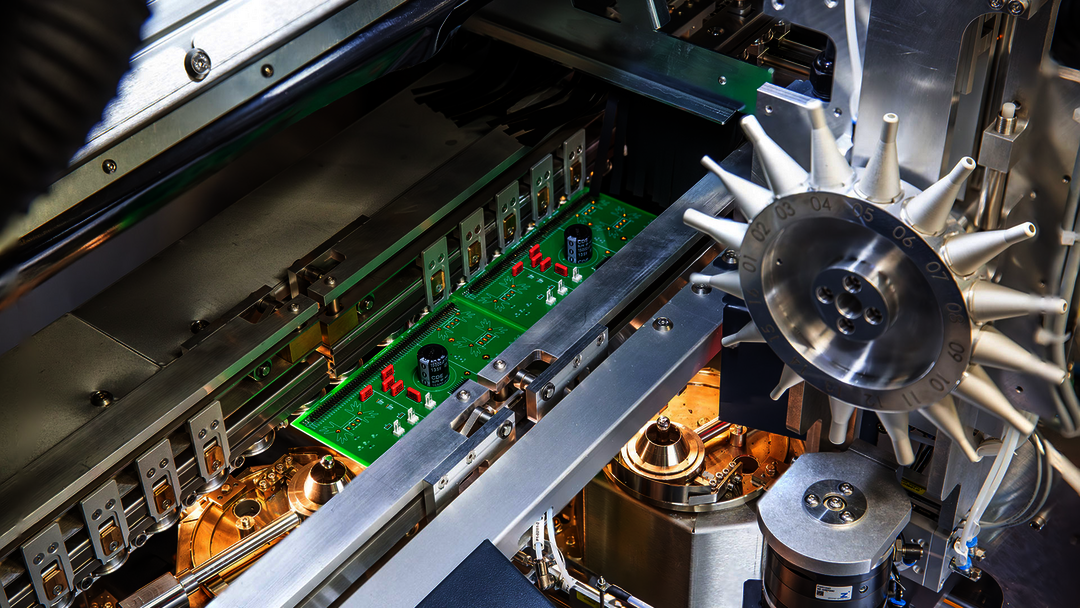

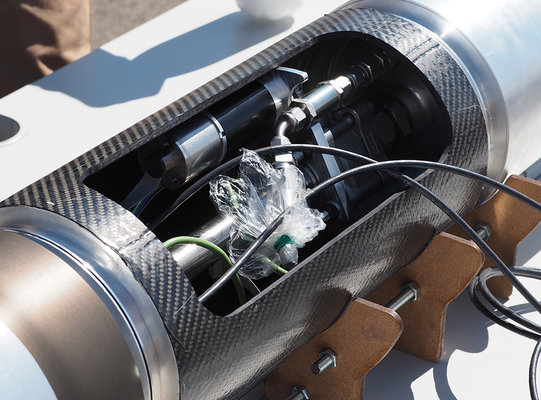

The next step in autonomous production is automatic flux nozzle cleaning and the automatic nozzle changer, which replaces solder nozzles completely without manual intervention – both during the running process and during setup. This reduces downtime to a minimum and supports production environments with frequent product changes and limited operator presence. Optimal thermal control is ensured by the newly developed matrix bottom heating system, whose six individually controllable segments heat each assembly precisely according to its requirements. This reduces thermal stress, ensures more uniform temperatures, and increases energy efficiency. With these innovations, the VERSAFLOW FIVE defines the next era of selective soldering: more automation, shorter setup times, maximum quality - and an enormous range of applications without changing machines. The ideal solution for electronics manufacturers who need the highest performance today and want to remain competitive tomorrow!