Successful SMTA appearances in MX + the US

With two impressive SMTA trade fair appearances - one in Guadalajara (Mexico) and one in Rosemont, Illinois (USA) - Kurtz Ersa, Inc. (KEI) got off to a dynamic start to its fall business. At SMTA Guadalajara on September 17 and 18, the KEI team presented state-of-the-art soldering, reflow, and rework technologies and welcomed over 4,000 trade visitors to its booth. In the USA in mid-October, over 5,000 trade visitors were counted.

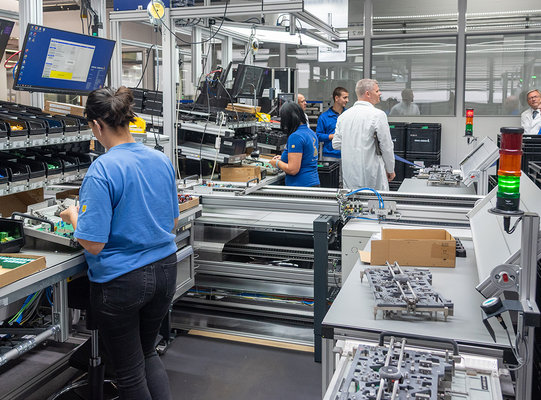

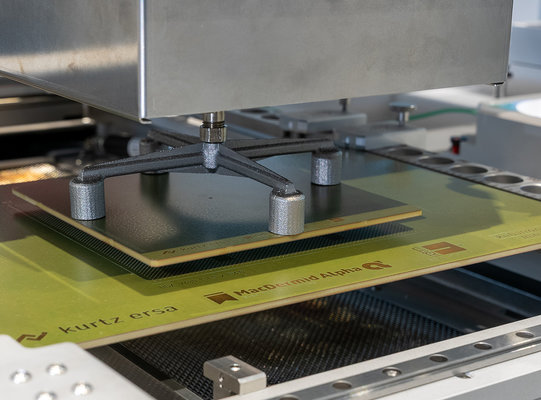

A particular highlight was the HOTFLOW THREE, currently Ersa´s most advanced reflow soldering system. Manufactured at the new plant in Juárez, Mexico, the HOTFLOW THREE combines intelligent temperature profiles with high energy efficiency and a compact design - ideal for demanding high-mix production. Equally impressive was the VERSAFLOW 4/55, a modular selective soldering system for maximum flexibility and throughput. The Ersa VERSAFLOW ONE with single-wave soldering module was also on display. With options for multiple solder pots soldering simultaneously at different locations, multiple soldering modules, and process monitoring, the system is designed for efficiency and repeatability in production. The selective portfolio was complemented by the innovative, low-residue ICSF Select6 from Interflux, which enables precise selective soldering processes.

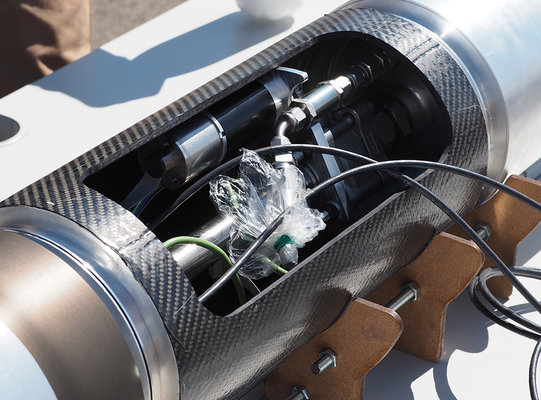

The award-winning HR 600P, a fully automatic rework system for BGA, QFN, and other fine-pitch components, was also presented. The system combines motorized X/Y/Z handling with top and bottom heating for precise removal and placement. The system offers complete traceability throughout the entire process and features an optional AUTO SCAVENGER for solder removal. “The HR 600P sets new standards for precision and ease of use,” emphasized Todd DeZwarte, Director of Sales at Kurtz Ersa, Inc. “The award underscores our commitment to providing technological solutions that deliver real added value.”

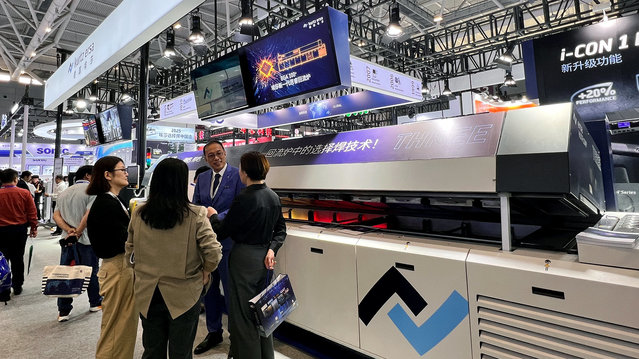

Kurtz Ersa at NEPCON Asia 2025: From Hype to Real AI Electronic Manufacturing

At NEPCON Asia 2025 in Shenzhen, China, one thing became clear: behind the fading buzz, electronics manufacturers are facing real challenges from AI and cloud computing. Conversations at the Kurtz Ersa booth centered on the rapid growth of processor and GPU packages, which are often 100 × 100 mm or larger, raising the bar for thermal performance and process control.

The HOTFLOW THREE reflow platform is highlighted as a solution for soldering complex, large-size BGAs with strong thermal performance and low delta T across both the PCB and large packages. Kurtz Ersa produces its reflow ovens in Zhuhai, near Shenzhen, enabling fast delivery, a quick response to market needs, and a competitive price-performance ratio.

For high-value AI and cloud computing printed circuit boards (which often cost several thousand dollars and require repair), advanced rework solutions like the newly released HR 600P were presented to help protect investments and reduce waste.

Another key message was that Kurtz Ersa´s selective soldering machines are now also being produced in China, extending the “local for local” approach to the VERSAFLOW machine platform. The core message at the trade fair stand was “Made in China 2025”. Production in Germany, China, and Mexico follows a global standard for quality and processes. In China, manufacturing in Zhuhai enables faster delivery, better availability, and high added value – and brings customers in the region closer to German technology for high-tech electronics production enabled by AI.

TechDays India: Successful Summer Edition

The Summer Edition of India Techdays kicked off on July 15 in Bangalore with a warm welcome and a traditionally atmospheric Lighting Ceremony. Customers praised the excellent cooperation with the Kurtz Ersa India team and the performance of our machines, especially the HOTFLOW. This was followed by technology presentations on reflow soldering and hands-on sessions on rework systems.

On July 17 in Coimbatore, we welcomed 40 participants, where the focus was on the EXOS and HOTFLOW reflow systems and the i-CON TRACE IoT soldering station. Here, too, there was an intensive exchange with customers, in this case on complex assemblies in rework systems. Many thanks to all participants for the valuable discussions!

Kurtz Ersa India with a strong presence at Productronica in Bangalore

With a successful trade fair appearance at Productronica India (September 17-19), Kurtz Ersa India has successfully confirmed its role as a reliable partner in the Indian electronics market. The leading trade fair attracted over 50,000 trade visitors and provided the perfect platform to showcase the company´s broad portfolio of soldering technologies and services.

“Anyone who buys from Kurtz Ersa India talks directly to the manufacturer - and benefits from process expertise, support and spare parts at manufacturer conditions,” explained Rainer Krauss, Ersa General Sales Manager and Managing Director of Kurtz Ersa India. He adds: “Buying a machine is a 15 to 20-year commitment. That´s when it´s best to do business with the manufacturer.”

Medium-sized EMS companies are proving to be the growth drivers in India: Many companies with several SMT and THT lines are already planning to expand their production capacities with a view to 2026. While low-cost suppliers often choose simple electronics without traceability, quality-oriented medium-sized companies rely on digitization, traceability and systems from market leaders such as Ersa. Since 2018, Kurtz Ersa India has consistently pursued the strategy of first building up service and process knowledge locally and then strengthening sales. Since fall 2025, 22 employees have been available for the whole of India - supplemented by service hubs in Delhi, Hyderabad, Chennai and Pune.

One highlight is the “Tiger Edition” of the VERSAFLOW ONE X series, which was specially developed for India and combines flexibility with high throughput. The portfolio is rounded off by the HOTFLOW series, the POWERFLOW ULTRA for industrial wave soldering processes and high-performance rework solutions. Ersa can also report an increase in its market presence in the field of hand soldering. Overall, Kurtz Ersa India is systematically expanding its role as an important player in the Indian electronics market with continuous growth, quality and customer proximity.