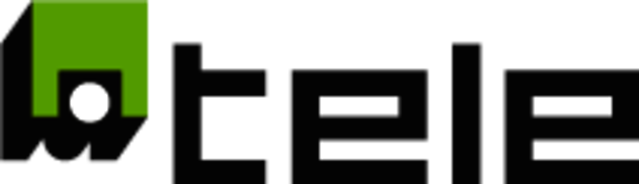

For over 60 years, TELE monitoring solutions have been ensuring safety and energy efficiency in many areas, whether in mobility, facility management, or renewable energies. TELE products – time relays, monitoring relays, load monitors, power electronics, and network and system protection – optimize the service life of machines and systems as well as the energy consumption of buildings. TELE has been relying on Ersa systems in electronics production for many years, most recently adding a HOTFLOW THREE reflow soldering machine and a VERSAPRINT 2 PRO2 stencil printer to its Vienna-based machine park.

The partnership between TELE and Ersa began in 2003 with a HOTFLOW 2/14 reflow soldering system. Today, more than 20 years later, TELE has a total of five Ersa systems in use - including two VERSAPRINT 2 stencil printers and, since the end of 2023, a HOTFLOW THREE reflow soldering system with 20 heating zones. The Ersa reflow flagship impressed with its patented three-stage Smart Cleaning System, which enables maintenance intervals of up to twelve weeks in 24/7 non-stop three-shift operation. The latest investments expanded TELE´s machine park as part of a long-term modernization concept. “We replace our machines in a cycle of six to seven years – strategically independent of products or orders,” explains Gerhard Sattler, who is responsible for process technology at TELE and has been with the company since 1988.

Flexibility and process reliability as top priorities

TELE produces on two SMT lines, each with an integrated VERSAPRINT 2 stencil printer and complementary soldering technology. Up to ten product changes per day are not uncommon. However, thanks to stored soldering programs, the changeover process is completed in a matter of seconds. “It´s just a push of a button – the machine runs empty, and all parameters are loaded automatically. In ten seconds, everything is ready for the next product,” says Gerhard Sattler, who has been involved in the development of SMT production from the very beginning.

Production at TELE is carried out in a flexible single-shift system with up to 50 hours per week, which responds to customer needs and at the same time offers flexibility for employees. Everyday production at TELE is characterized by small to medium batch sizes - from single items to orders of 5,000 pieces. Individual runner types can also reach quantities in the hundreds of thousands, but this is the exception at the Austrian company. Regardless of the batch size, the most important criterion in line equipment at TELE is maximum availability. “Since we only operate two lines, every failure or non-failure counts for us. And this is exactly where Ersa systems have proven to be extremely reliable,” emphasizes Gerhard Sattler.

Energy efficiency and stable soldering processes

The new HOTFLOW THREE impresses not only with its stable temperature profiles - a must in ISO-certified operations - but also with its high energy efficiency. The strong thermal insulation noticeably reduces energy input, and there is hardly any radiant heat. As advertised by Ersa, maintenance intervals are twelve weeks or more. Another plus: the nitrogen control, which had to be controlled manually in earlier models, now works almost maintenance-free. “The installation of the HOTFLOW THREE took only one week - after that, we were able to start again with identical parameters as if nothing had happened,” says Gerhard Sattler. Despite initial challenges, the machine´s dual-track transport for handling PCB widths of up to 686 mm was also successfully implemented - with strong support from Ersa and its long-standing Austrian partner Stepan GmbH.

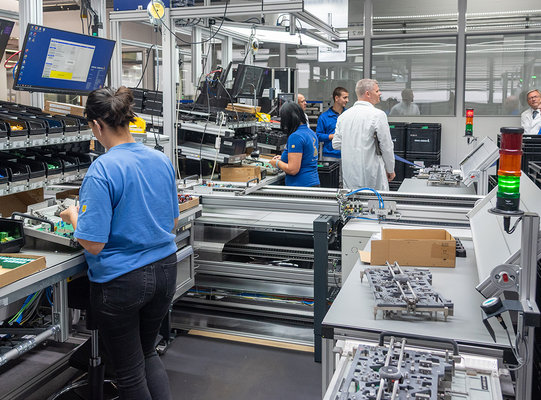

Print quality as a success factor

Another key component in TELE SMT production is print quality. Back in 2008, TELE invested in a VERSAPRINT S1, which at the time was the only system on the market to feature integrated 100% optical print control using a line scan camera. Today, two VERSAPRINT 2 PRO2 systems are in use - coordinated on the server side and thus efficient to operate in terms of handling and service. “Since we started working with VERSAPRINT, soldering errors are basically no longer an issue for us,” is TELE´s clear conclusion.

Reliability and partnership as a basis

What TELE particularly appreciates about its collaboration with Ersa and Stepan is the cooperative approach and rapid support in the event of a service call. “A defective monitoring module in our old HOTFLOW - the only problem in 15 years - was repaired within a day. That´s exactly what makes a sustainable partnership for us,” says Gerhard Sattler. “Over two decades of working together, a relationship of equals has developed here - we know each other, trust each other, and support each other.”

With production growth of 10% last year - following 15% in the previous year - TELE is looking positively to the future. The combination of technical expertise, flexible manufacturing, and long-standing partnership forms the foundation for sustainable success - both at the Vienna site and in the global export business.