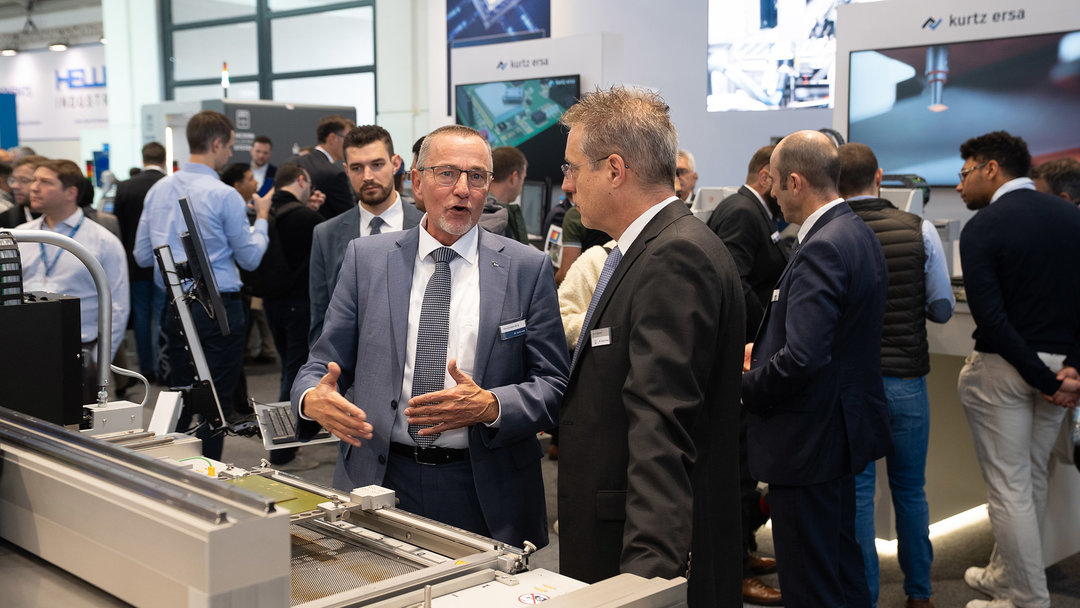

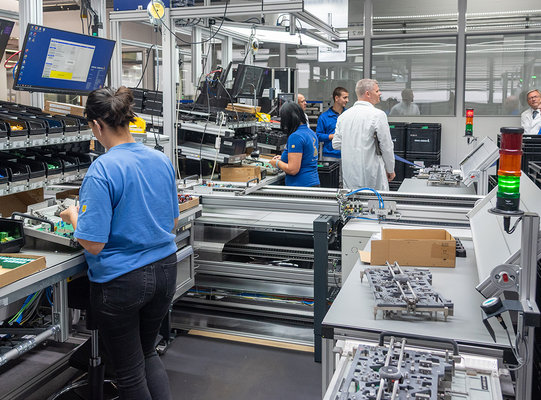

With numerous world firsts, an excellent response, and impressive live demonstrations, Ersa made a big impact at the 50th Productronica in November. Under the trade fair motto “Our Innovation, Your Solution.” the company presented innovative technologies that show where electronics production is heading – and how Ersa is actively shaping this future.

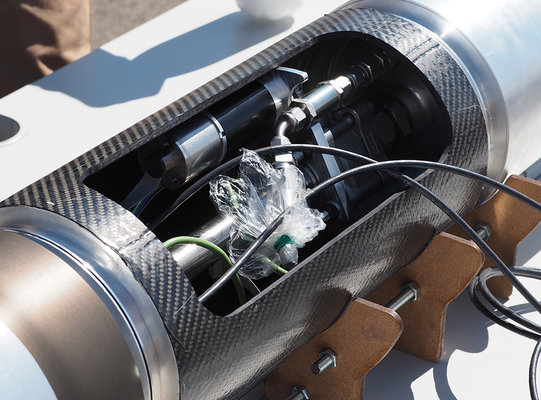

Among the numerous trade fair innovations, the new wave soldering and selective soldering systems in particular caused a stir among the many visitors to the Ersa booth. The POWERFLOW ONE marks the ideal entry point into professional wave soldering - equipped with proven Ersa technology, the compact ONE wave soldering system offers high process reliability and is perfectly suited for smaller EMS companies. The POWERFLOW FIVE was presented as the new high-end wave soldering system for demanding applications in power electronics, e-mobility, and 5G infrastructure. Features such as adaptive process control, dynamic z-axis, programmable wave heights, and an energy-efficient hybrid heating system enable maximum flexibility and cost-effectiveness. The robust heavy-duty transport system for PCBs weighing up to 25 kg was particularly well received.

The VERSAFLOW FIVE sets the new benchmark in selective soldering. The system can handle an exceptionally wide range of formats and variants - from standard boards to 685 mm long XL boards - and proved this in live hands-on sessions. The VERSAFLEX 2.0 module, the intelligent matrix preheater, and the automatic nozzle changer significantly reduce setup times and demonstrate how autonomous process steps in electronics production are already becoming a reality today.

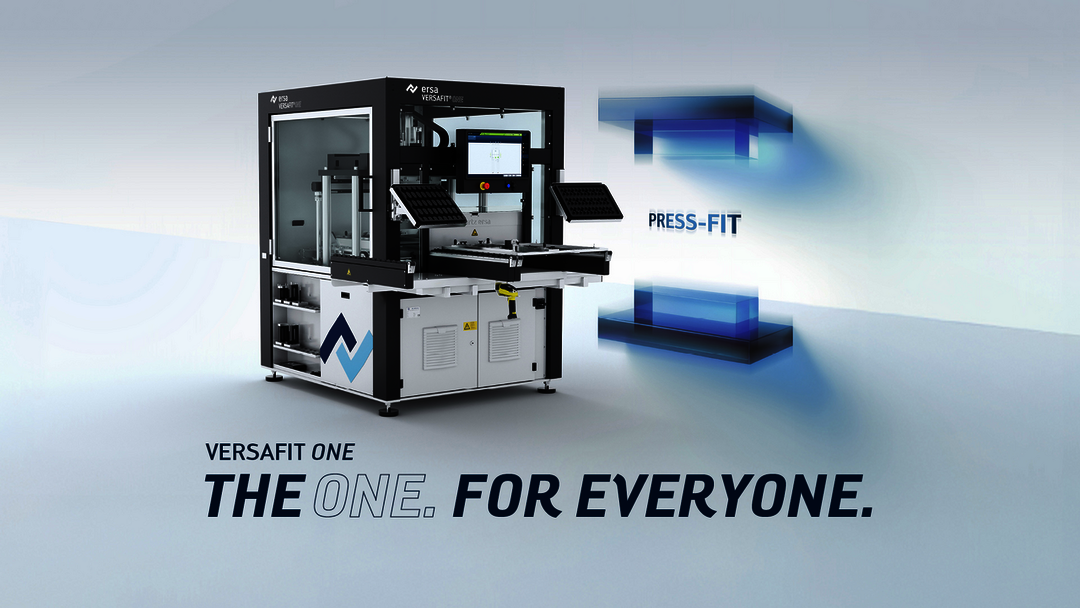

Innovation Award for the new VERSAFIT ONE

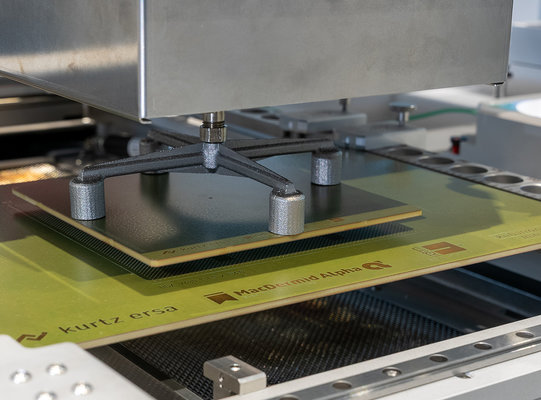

A particular highlight was the Innovation Award that Ersa received for the new VERSAFIT ONE. The semi-automatic press-fit system transfers the precision of high-end inline technology to a compact batch concept, thus precisely meeting the needs of many medium-sized manufacturers. Thanks to force-displacement-monitored process control with up to 20 windows, formats up to 610 x 610 mm, and absolutely reliable connections without thermal stress, the VERSAFIT ONE press-fit system proved to be a highlight for high-power applications in photovoltaics, charging infrastructure, and energy technology.

Rework, tools, and automation with impressive details

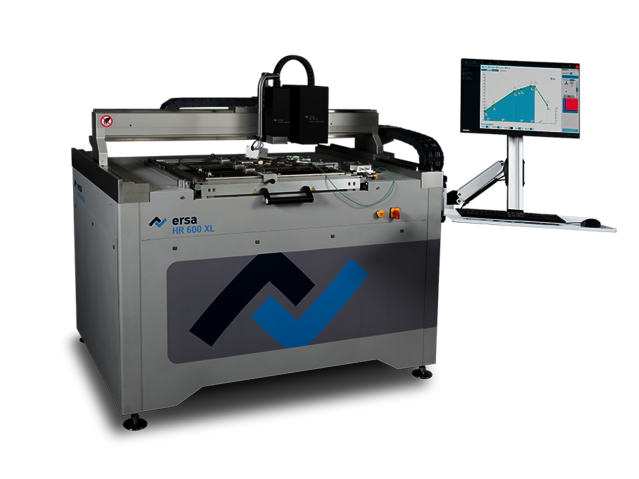

Ersa also made a significant impact in the rework segment. The HR 600P with its innovative scavenger feature and the large-format HR 600 XL demonstrated how efficient and reproducible modern rework can be. The i-CON TRACE, the first IoT soldering station with IPC-CFX certification, attracted particular attention from many production managers. It enables complete traceability and MES integration - and with the “robot-ready” i-TOOL, it is also designed for automated manual soldering processes.

With modular solutions for line and factory automation - from conveyor systems to lifting and turning stations to VERSAGUIDE/VERSAEYE - Ersa impressively demonstrated how flexible production lines can be set up efficiently and productively today. In addition, Kurtz Ersa Semicon GmbH, the newest member of the Kurtz Ersa Group, presented its portfolio for semiconductor manufacturing, which met with great interest.

A trade fair that sets standards

In addition to the technical highlights, the traditional Ersa party at the trade fair stand was once again a crowd puller, which certainly matched the rush during the day at the trade fair. In a relaxed atmosphere, numerous customers took the opportunity to cultivate contacts, forge new partnerships, and bring the successful trade fair days to a close together - a particularly atmospheric moment in the anniversary year of Productronica.

With its broad portfolio of innovations and a strong trade fair presence throughout all four days, Ersa impressively demonstrated where the journey in electronics production is headed: toward more efficient, flexible, and digitally networked processes. Whether wave or selective soldering, press-fit technology, rework, tools, or automation - the presentations at Productronica 2025 make it clear that Ersa is not simply responding to general industry trends, but is actively shaping the future of the industry. “50 years of Productronica illustrate the technological progress of our industry. The leaps in innovation are becoming greater and occurring in ever faster cycles - and Ersa delivers the solutions that enable the future of electronics production. To this end, we use our globally growing service and sales network to provide targeted support to our customers in all markets, wherever they are in the world,” said Ersa´s Head of Sales, Rainer Krauss.