Ziehl-Abegg, headquartered in Künzelsau, Germany, is one of the leading companies in air, control, and drive technology, whose products are used worldwide in heating and cooling systems, clean rooms, and agricultural facilities. As early as the 1950s, the company laid the foundation for modern fan drives with external rotor motors that set global standards in terms of efficiency and sustainability. Following a 21-meter-long EC-THT assembly line in 2016, Ziehl-Abegg has now implemented another fully automated production line in close cooperation with system supplier Ersa, which exceeds the previous one by 8 meters.

2024 was a difficult year for almost all industrial companies - business was particularly subdued in Germany, and Europe also fell short of expectations. Nevertheless, Ziehl-Abegg opened a new plant in the USA last year - the largest single investment in the company´s 115-year history, at 100 mio. Euro. In Vietnam, another Ziehl-Abegg production facility went into operation for Asia in spring 2024. Ziehl-Abegg is also optimizing local production in its home market - in Southern Germany alone, the company has 47,000 m² of production space.

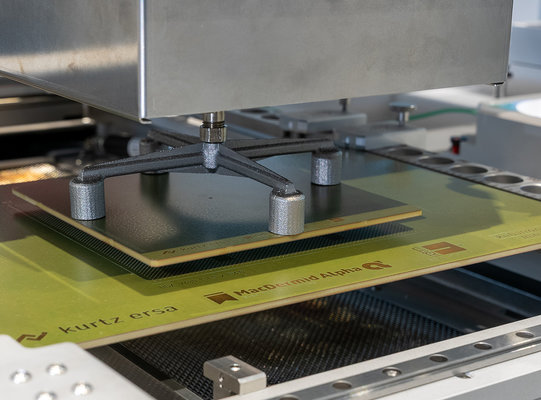

About the project: Back in February 2023, the green light was given for a new assembly line based on an existing Ersa POWERFLOW wave soldering system with directly connected automation. It was an ambitious project, the official start of which coincided with the final phase of the coronavirus pandemic. Once again, the project partner was system supplier Ersa from Wertheim am Main, which had previously delivered four wave soldering systems to Ziehl-Abegg in Künzelsau in the Hohenlohe region, starting in the early 1980s. After several successful projects, a second, fully automated production line was now to be set up at the Künzelsau site. This was a tightly scheduled project that was to completely replace a 25-year-old semi-automatic peripheral system within just ten months. In addition to the ambitious timing, the project marked a real technological leap forward: where goods carriers had previously been loaded by hand, sophisticated transport and peripheral technology was now to take over all work steps system-wide with fully automated workstations, buffers, and a zero-error strategy.

Decision in favor of productivity

Adrian Schaaf, who has been with Ziehl-Abegg for six years and, since April 2023, has also been responsible for SMT circuit board production and the assembly of control units in the electronics plant as head of the Industrial Engineering department, was entrusted with customer project management. Stefan Weiß also brought his many years of experience to bear. He began his training with the air conditioning and ventilation technology expert in Künzelsau in 2007 and has since risen to become team leader for THT production. Support for the project came from the very top: Joachim Ley, former COO and now CEO, was already responsible for electronics production as Chief Production Officer and continues to keep an eye on this as CEO. The first point of contact is now Sebastian Wohlleben as Vice President Operations Central Europe - here too, there was full management support for the project.

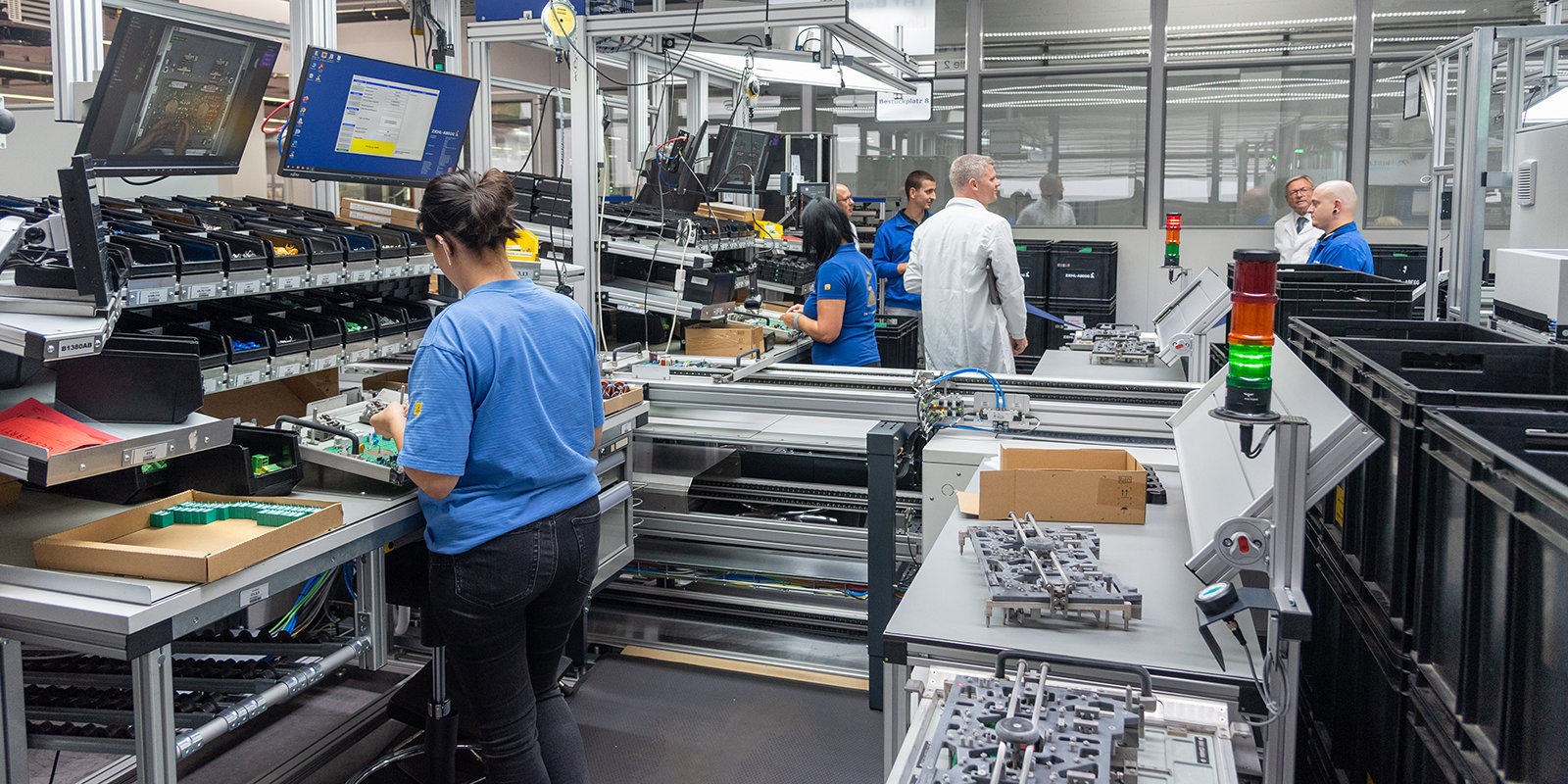

The new line comprises eight placement tables with automated placement control (six of which are fully automatic with a multi-stage buffer system across three levels), various lifting, lowering, and turning stations, and RFID technology for secure traceability. It is complemented by a clever transport concept, which also implements a bypass function in the event of a jam, modification of the solder frames using a cross transport bar, and the integration of an AOI system from Viscom. Central control components such as line controllers and PLCs ensure the smooth coordination of all process steps. Thanks to this infrastructure, products can be manufactured flexibly and in high variance - while maintaining stable cycle times. “The decision in favor of the new line was clearly based on productivity considerations,” explains project manager Adrian Schaaf. “The previous system ran extremely reliably for over 25 years, but the requirements for output and automation have evolved significantly, so action was needed.”

Strategic course setting

Although the capacity of the old line was expanded in 2021 with additional assembly stations, essential functions such as database connection, THT-AOI, and process interlocks were missing. The old system was also no longer up to date in terms of ergonomics due to manual carrier handling. The new solution now achieves a level of quality that corresponds to the highly automated EC-THT line – including end-to-end process traceability and ergonomic relief for employees. “The development of the line was very exciting – we first held workshops to determine how we could use existing elements in the available space to create a new solution that would significantly boost productivity. The higher degree of automation was crucial - with weekly regular meetings, we worked our way deeper and deeper into the subject matter and defined the entire line based on fine details and sophisticated processes,” say Ersa Sales Manager Stefan Wurster and Sales Project Manager Dominik Farrenkopf, looking back on the close cooperation during the quotation phase.

The spatial conditions posed a particular challenge - the 90° rotation of the tables left little space between the workstations. In the end, a wall was even removed to make optimal use of every centimeter of production space. Fortunately, the existing workpiece carriers could be retained with minor modifications.

Delivery took place on December 22, 2023, and installation began immediately afterwards. After a short break for Christmas, the hardware was installed in just nine days – a feat of strength that saw a team of nine technicians, project managers, and sales staff working together on site. On January 8, 2024, the line went into shift operation as planned – an ambitious schedule that Ziehl-Abegg and Ersa successfully kept to thanks to close coordination and a high level of commitment. “Some production areas and even an entire plant depend on the smooth running of this line – a delay or even a standstill were not options. Thanks to the cooperative partnership, we were able to meet the ambitious schedule, and today the line is running in 2-shift operation. Many thanks to everyone involved – especially the production team, which has always shown great commitment,” reports Adrian Schaaf.

Digitization: A boost for productivity

In addition to hardware integration, software was a key issue that presented a number of challenges. The LINE CONTROL control system was introduced with the line, which was gradually put into operation and ultimately closely linked to the MES system. In addition, PCs with worker cockpits are integrated, which communicate with the production database via specially programmed Ziehl-Abegg software. This architecture allows for flexible operation, quick updates, and, in the long term, preparation for AI-supported optimizations. The MES connection has now also been established.

The new line brings several advantages for Ziehl-Abegg: higher productivity, greater flexibility with varying batch sizes, relief through additional buffers, and a significant boost in quality through fully automated processes and testing systems. Ziehl-Abegg has 330 assembly variants for PCBs in THT production – 300 of these can be handled by the new line, from batch sizes of five to 2,000, while high-runners are manufactured on the EC/THT line from 2016. The ergonomic improvements are particularly noticeable: since manual lifting and setting down of the solder frames is no longer necessary, the weight savings for the workers add up to over 1,000 tons per year. Although the throughput time has increased slightly, this is more than offset by the high flexibility and improved data quality. Process data from automatic placement control systems, soldering results, and AOI flow centrally into the production database and support Ziehl-Abegg´s consistent zero-defect philosophy.

Partnership on equal terms

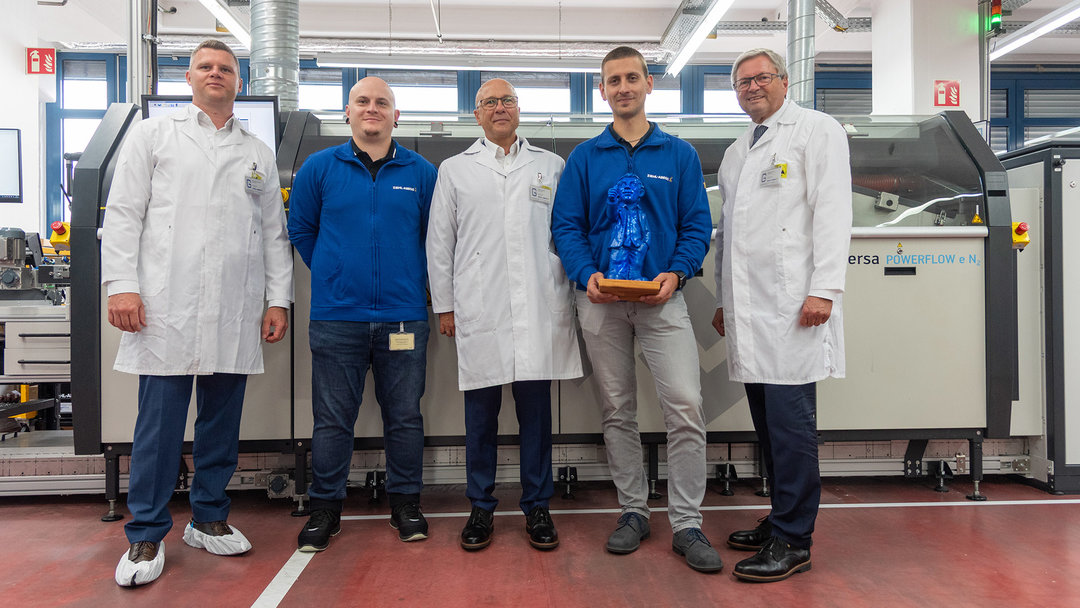

Ziehl-Abegg´s regional manufacturing strategy has been proven successful, as confirmed by the company´s win of the Manufacturing Excellence (MX) Award 2024, with which the high-caliber jury recognized in particular the digital process innovation and the holistic zero-defect philosophy. With the new fully automated line, Ziehl-Abegg is ideally positioned - both in terms of current market requirements and the use of AI, which is expected to grow dynamically in the future.

The partnership with Ersa remains a key factor in this: “We are in the premier league here - and we know that we can count on each other. The entire project took place on an equal footing and is perceived as a real flagship project in electronics production,” emphasizes Dominik Farrenkopf from Ersa Sales, who, as project manager, provided direct on-site support during the crucial implementation phase until final acceptance over several weeks and was thus available at all times to initiate organizational matters directly. There were always critical moments and challenges – but in the end, the main thing was the goal we achieved together: to hand over the system, which had been tested for several weeks and finally approved, to production.

After more than 40 years of collaboration, Ersa remains a reliable partner for Ziehl-Abegg in all matters relating to electronics production. Ideas for upcoming projects are already being exchanged - however the project is ultimately defined and however strong the AI component may be: Ersa is once again firmly at Ziehl-Abegg´s side as a system supplier, continuing the joint success story!