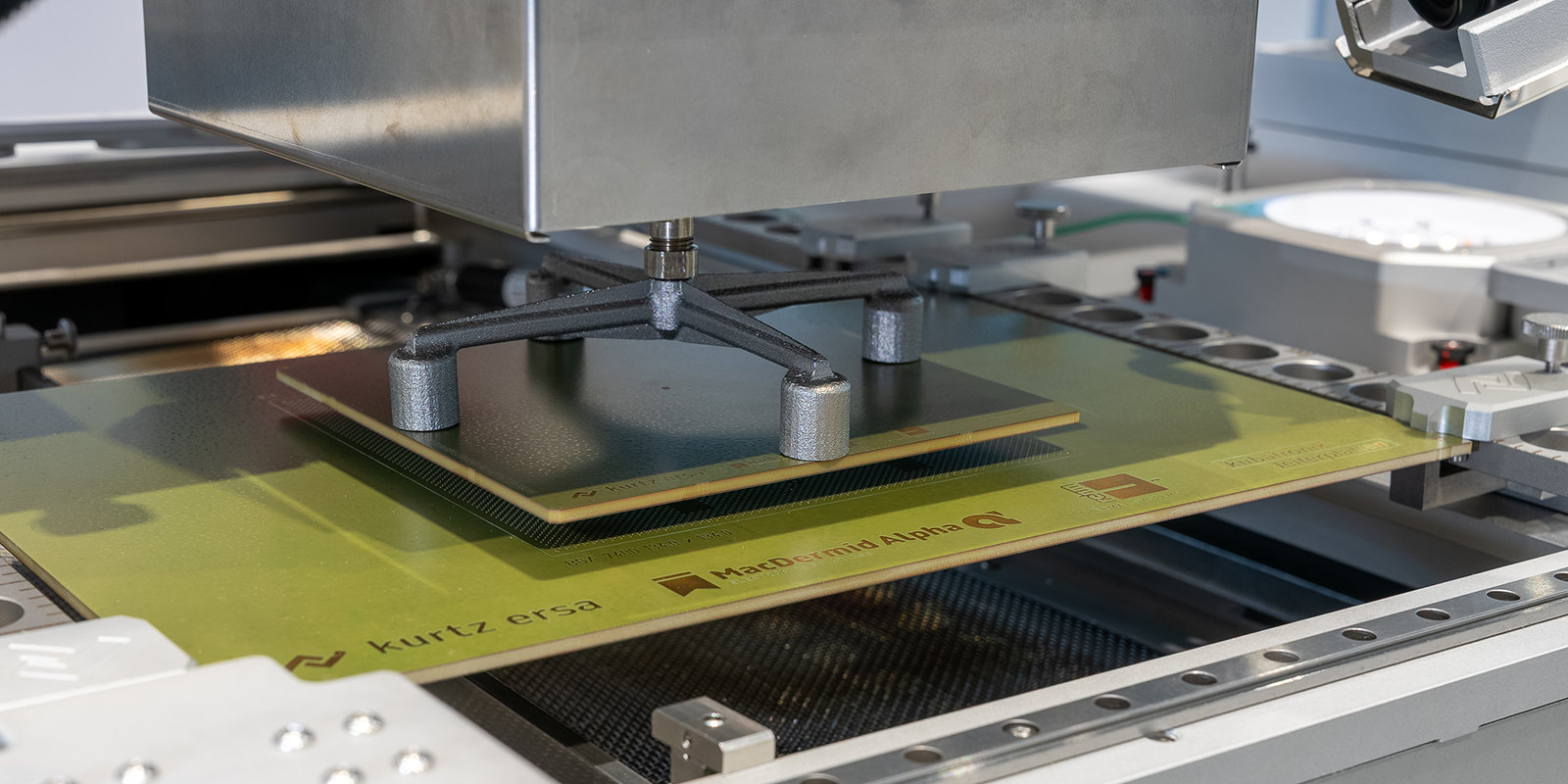

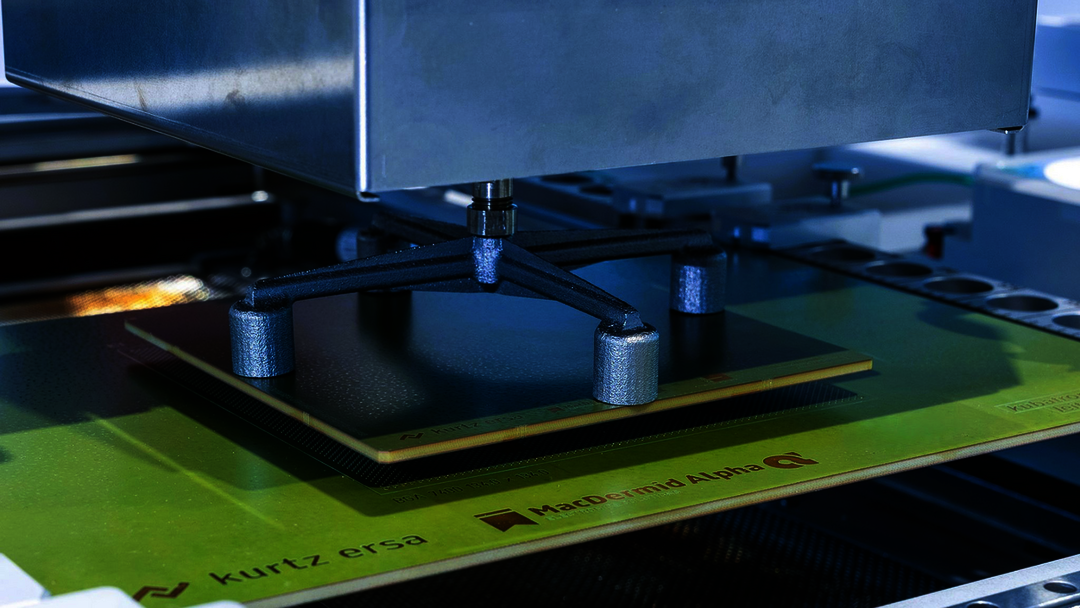

Tech companies are currently investing heavily in AI infrastructure. Many projects are in the pipeline, and processing the high-performance processors required for AI applications is a challenge for the industry. With dimensions of 150 x 150 mm, a weight of up to 500 g, and more than 20,000 individual solder connections on each component, these AI chips place high demands on the manufacturing process. From solder paste printing and the assembly of such components to homogeneous and distortion-free soldering, all parameters must be adjusted and optimized. And if an error does creep into the SMT line, the high cost of components and assemblies argues in favor of qualified rework.

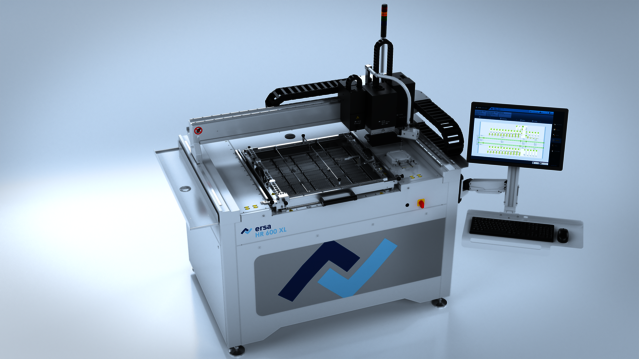

BIG-BGA-Rework für KIHR 600 XL

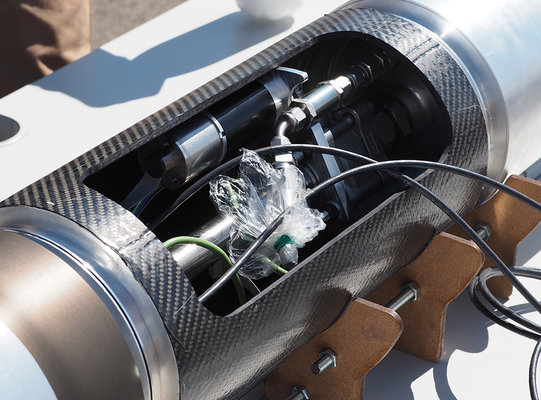

The HR 600 XL from Ersa offers everything you need for this - with matrix preheating, large assemblies are heated gently and homogeneously. A newly developed hybrid heating head with an effective area of 160 x 160 mm and up to 4,800 W of heating power provides the necessary energy coupling for soldering and desoldering processes. The AUTO SCAVENGER module removes residual solder without contact after a component has been desoldered. Finally, the new “pin-to-pad” placement process using image processing allows precise positioning of the new giant components. With the HR 600 XL, the future of artificial intelligence can begin!

SMART SOLDERING STARTS NOW!i-CON TRACE

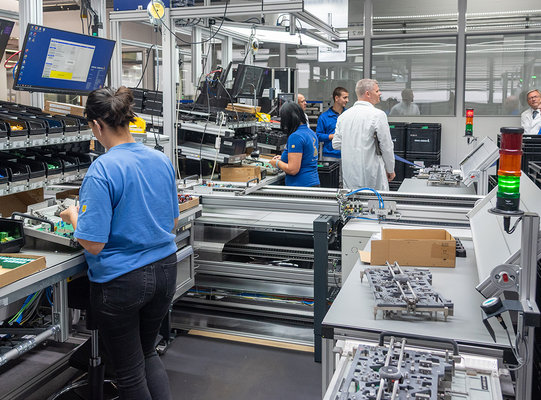

Comprehensive documentation/MES connection

Seamless process data documentation is a key feature of future electronics production. The i-CON TRACE closes the last gap in the manual soldering process and can be integrated into MES-controlled production processes. This means that either a record of the entire soldering task can be downloaded in a desired file format and stored in a higher-level control system, or real-time communication between the soldering station and the customer´s MES can take place via IPC/CFX.