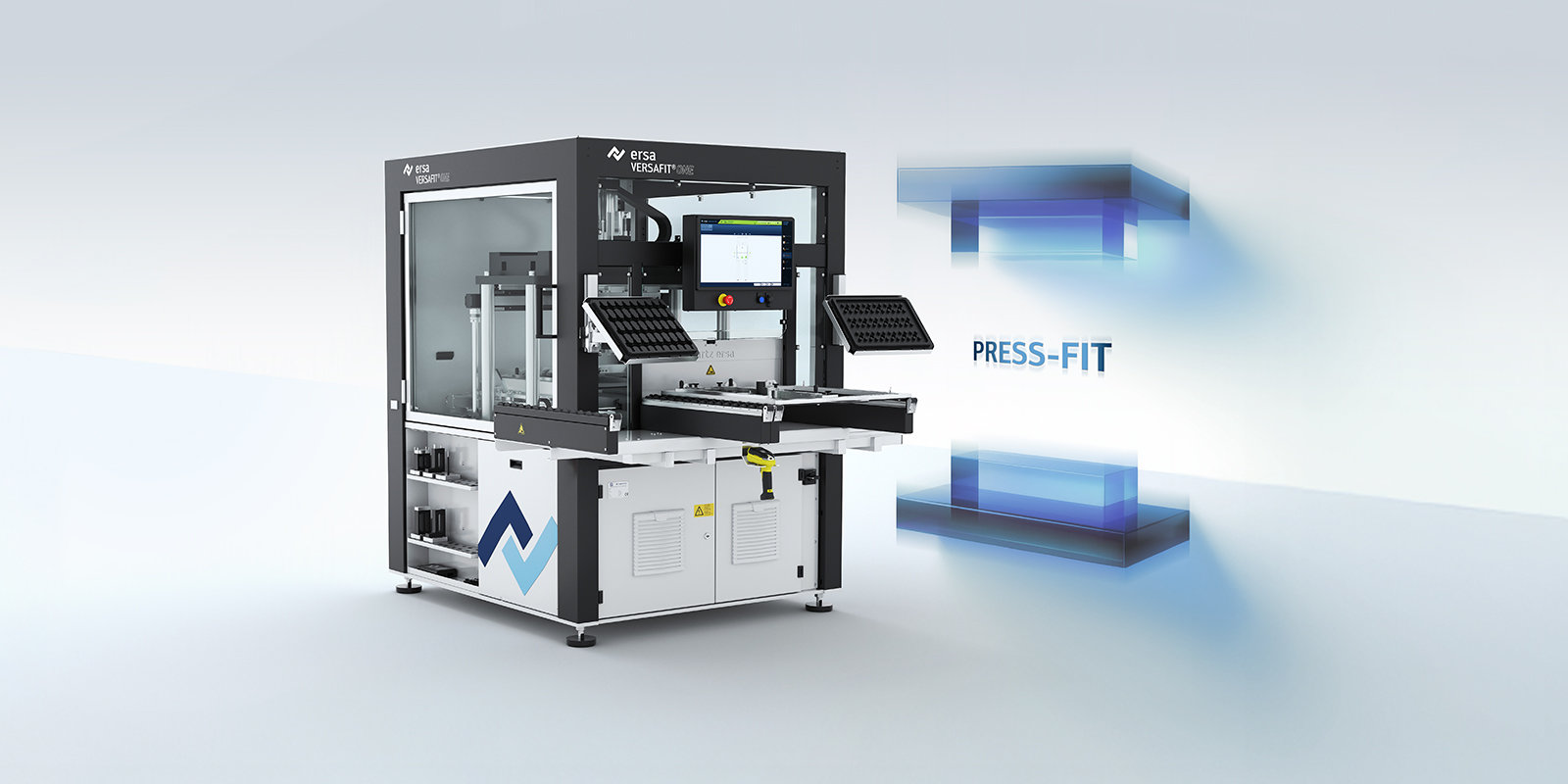

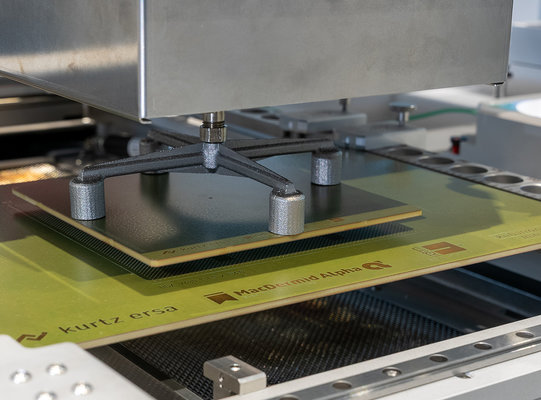

With the new VERSAFIT ONE, Ersa is expanding its portfolio with a semi-automatic press-fit system that combines maximum process reliability, compact design, and economic efficiency. The press-fit system was named the winner in the “SMT” cluster at this year´s Productronica Innovation Award and represents a and represents a genuine thermally gentle alternative to soldering for robust, thermally gentle high-current connections and short cycle times. According to the jury, the basis for the award was a modern machine concept designed specifically for the requirements of medium-sized electronics manufacturers.

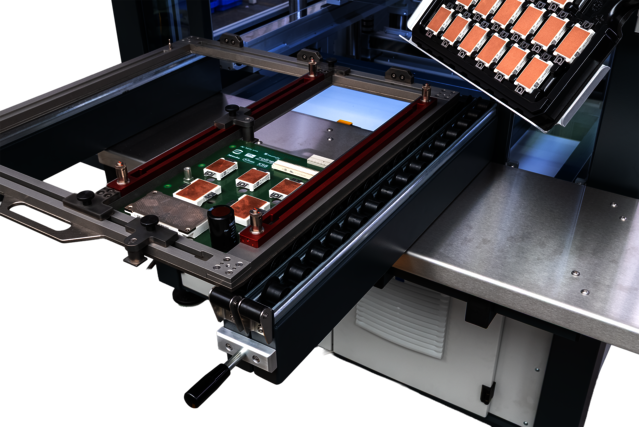

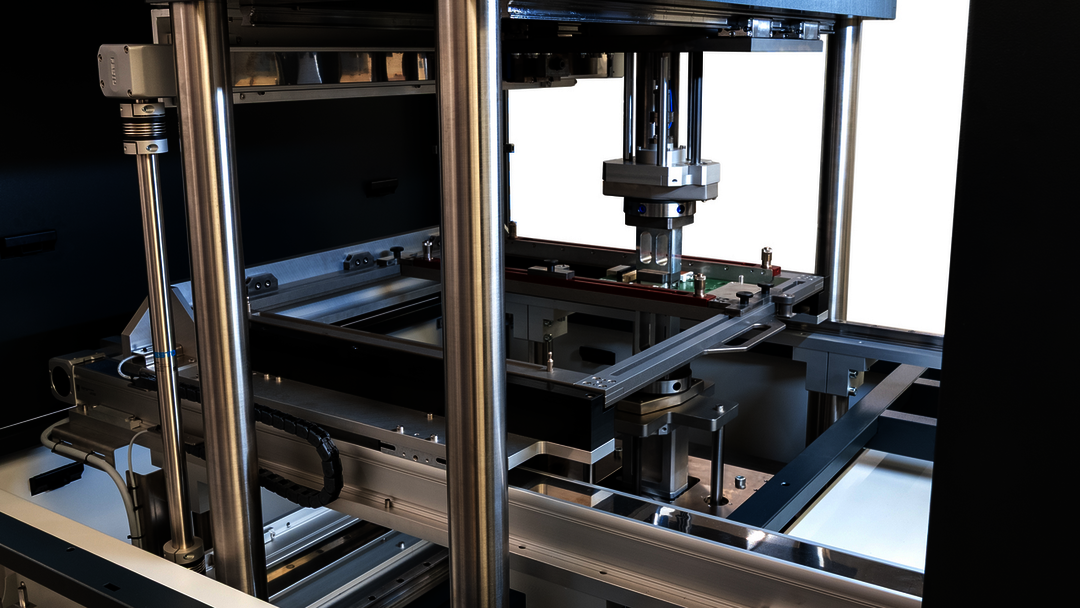

The VERSAFIT ONE is based on the technology of the high-end inline system VERSAFIT 500 and transfers its precision to a space-saving batch system. It is ideal for manufacturers with a high product mix and demanding applications such as photovoltaics, electromobility, charging infrastructure, or energy technology. Thanks to a fully monitored pressing process - including 100% force-displacement measurement and real-time OK/NOK evaluation - highly resilient, flux-free electrical connections with extremely low contact resistance are created.

With passage heights of 100 mm at the top and 120 mm at the bottom, and a assembly format of up to 610 × 610 mm, the machine covers a wide range of products. It is particularly suitable for pressing IGBT modules or high-pole connectors in power electronics. The robust platform, based on the proven Ersa batch selective soldering technology, offers maximum user-friendliness and reproducible results - regardless of the operator. The VERSAFIT ONE thus closes the gap between manual presses and fully automated lines: precise, economical, and future-proof. The engineering for the award-winning press-fit system was carried out by the automation experts at SCHILLER AUTOMATION, who thus provided outstanding proof of the intercompany expertise within the Kurtz Ersa Group. The result: a strong strong statement for anyone who wants to combine high quality and efficient processes in press-fit technology!

HIGHLIGHTS VERSAFIT ONE

- 100% process reliability at inline level in a compact, attractively priced system

- Operator-independent pressing process: reproducible results, secured by shutter

- High flexibility: quick manual tool change, optional tool rotation (0°/45°/90°), freely configurable programmes

- Seamless traceability: optional DMC scan package, CSV/OPCUA data output, remote service via VPN

- Maximum efficiency: no heating, no compressed air consumption, short cycle times, low energy consumption